Choosing a door closer isn’t just about picking a piece of hardware—it’s about making sure your door works safely, reliably, and comfortably for everyone who uses it. From the size and weight of the door to the environment around it, several factors determine which closer will perform best. In this guide, we’ll walk through the essentials of selecting, configuring, and enhancing a door closer so you can make an informed decision that balances durability, accessibility, and convenience.

1. Understand Your Door and Its Environment

Before selecting a closer, you need to know the basics about your door:

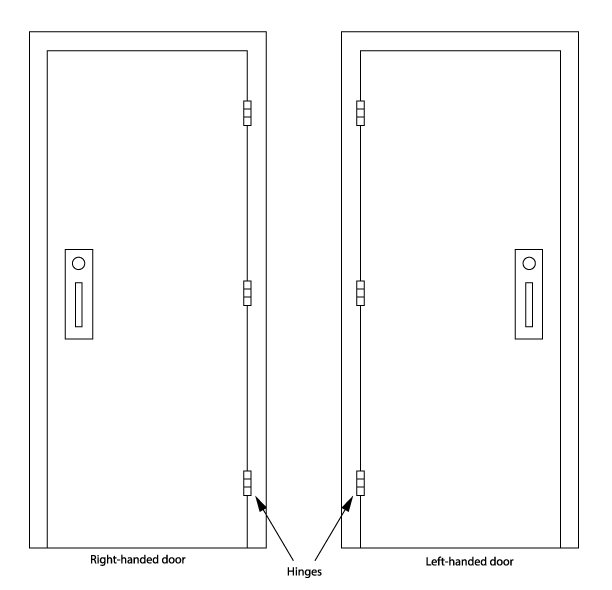

- Door handing: Determined by the hinge position when viewed from the pull side of the door.

- Hinges on the right = right-handed door

- Hinges on the left = left-handed door

- Door weight and size: Heavier and wider doors require closers with greater closing force.

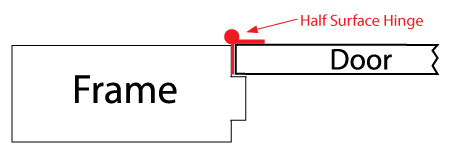

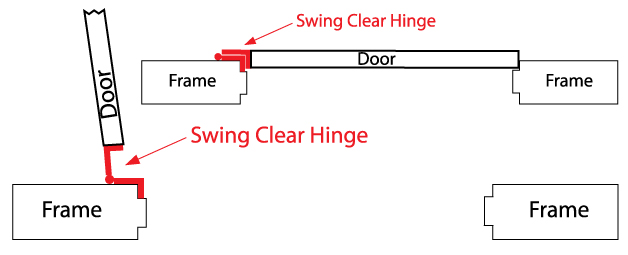

- Surrounding variables: These affect which closer type can be installed. Common considerations include:

- Clearance between the door panel and the top jamb

- Distance between the hinges and the adjacent wall

- Height between the door frame and ceiling

- Whether a door stopper is used

- Air pressure through the doorway (common in exterior doors or HVAC-controlled spaces)

2. Select the Appropriate Door Closer Type

Door closers come in several configurations, each suited for different applications:

- Surface-Mounted Closers:

- Standard Arm: The most common style, often found in hotel rooms and interior spaces.

- Top Jamb: Mounted on the frame above the door, commonly used with glass doors that don’t have stiles large enough to hold a closer.

- Parallel Arm: Typically installed in offices and on fire exit doors, offering a low-profile look with the arm mounted parallel to the door.

- Track Rail Arm: An alternative to standard or parallel arms, using a sliding track for a cleaner appearance.

- Concealed Closers: Installed within the door or frame for a streamlined look.

- Floor Closers: Installed beneath the floor surface, often used for heavy glass doors or double-acting doors.

- Double-Action Closers: Allow the door to swing both in and out, often found in restaurants and high-traffic areas.

3. Configure Your Door Closer

The closing force is the amount of power a closer uses to shut the door. Choosing the right setting ensures the door latches securely without being too heavy to open.

Key considerations for closing force:

- Adjustable strength: Most commercial door closers allow you to increase or decrease the force based on door size, weight, and usage.

- Standard sizes: Closing force is rated in sizes 1 through 6 under ANSI/BHMA standards.

- Size 1 = lightest force, often suitable for small interior doors

- Size 6 = strongest force, typically needed for heavy exterior doors exposed to wind or pressure

- Accessibility: The Americans with Disabilities Act (ADA) sets requirements for how much force is needed to open doors, so closers must strike a balance—strong enough to latch, but not so strong that the door becomes difficult to use.

- Performance balance:

- Too little force means the door won’t latch properly

- Too much force means the door can be unsafe or hard to open

4. Choose Your Extra Features

Beyond the basics, many door closers include additional functions that enhance safety, accessibility, and convenience:

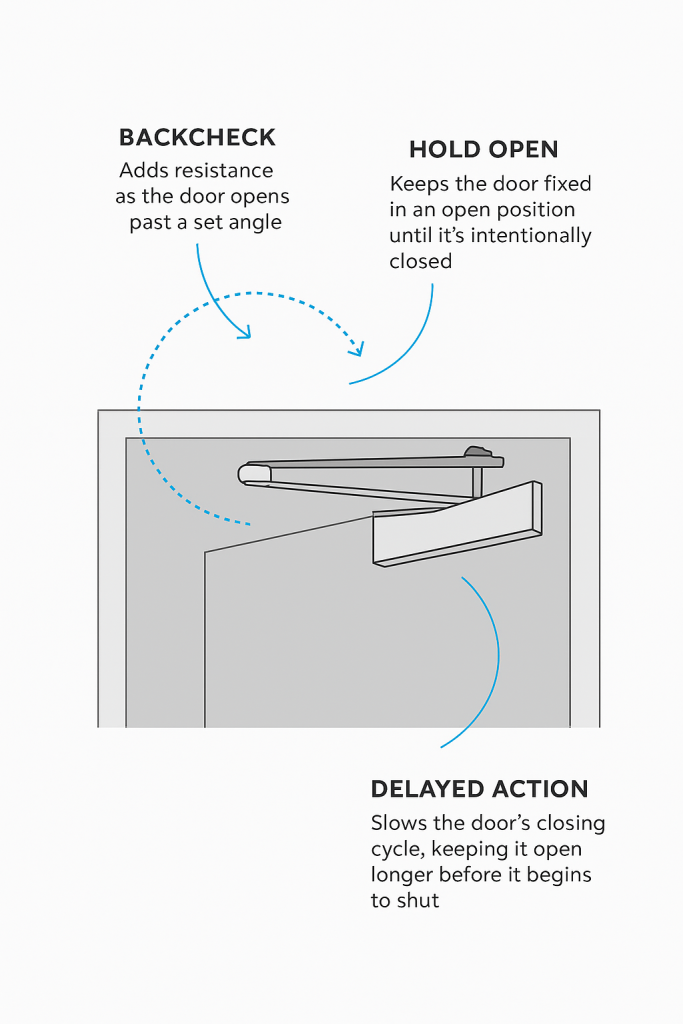

Backcheck: Adds resistance as the door opens past a set angle (around 70–75 degrees). This prevents the door from being flung open too forcefully, protecting the door, frame, hardware, and nearby walls.

Hold Open: Keeps the door fixed in an open position until it’s intentionally closed. This is helpful for moving equipment, increasing foot traffic flow, or ventilation. Note: Hold-open closers are not permitted on fire-rated doors.

Delayed Action: Slows the door’s closing cycle, keeping it open longer before it begins to shut. This allows extra time for people with mobility challenges, staff with carts, or groups moving through. Common in hospitals, assisted living, and other accessibility-focused facilities.