If you’ve ever held two keys that look nearly identical but still don’t work interchangeably, you’ve encountered the concept of the keyway. In door hardware, the keyway is far more than just the visible slot in a lock — it is a precisely engineered internal profile that controls which keys can access a cylinder, how systems are organized, and even how secure a facility remains over time.

What Is a Keyway?

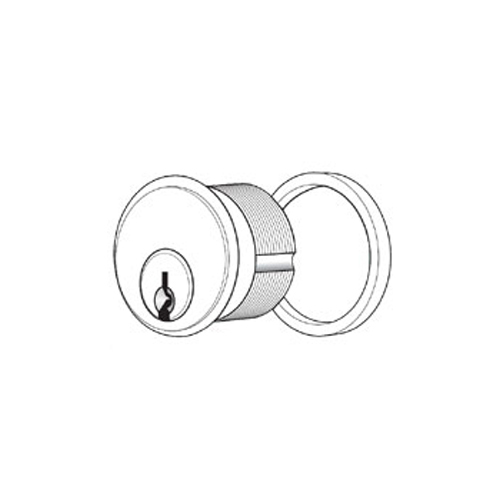

A keyway refers to the exact internal shape of the keyhole inside a lock cylinder. Think of it as the fingerprint of the locking mechanism: highly specific, intentionally designed, and impossible for an incorrect key to bypass.

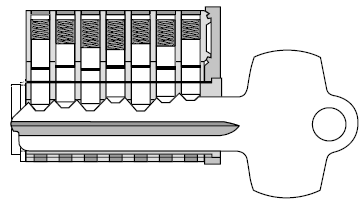

Though all keys share common elements like cuts and grooves, the keyway is what governs which key blanks can physically enter the cylinder. It acts as the first level of security and control before pins, tumblers, or electronic systems ever engage.

A Keyway Is Not the Same as Key Bitting

Two keys may share the same bitting (the cut depths along the blade), but if their keyway shapes differ — meaning their grooves and side milling don’t match — they won’t even enter the cylinder. The keyway acts as a mechanical gatekeeper, preventing incompatible keys from engaging the lock.

How Keyways Are Identified

When a cylinder is marked with a keyway code, that designation refers to its exact internal profile. The code tells locksmiths, security professionals, and manufacturers which key blank is required—and which ones are not permitted.

Keyway codes matter because:

- A key cut for a 12345 keyway won’t fit into a 15999, 11411, or any other differently profiled cylinder.

- Even small variations in milling or side grooves make insertion physically impossible.

- Key replacement, system expansion, or rekeying must always refer back to the original keyway design.

If the profile doesn’t match, the key stays out.

Why Keyway Design Matters

Keyways are not random; they are strategic. Manufacturers develop keyway shapes to balance security, access control, and system organization.

1. Key Control and System Management

Unique or restricted keyways help maintain system integrity. Institutions like hospitals, universities, and corporate campuses often choose proprietary or restricted keyways to ensure that:

- Keys cannot be duplicated without authorization

- System expansion remains manageable

- Access groups stay clearly segmented (i.e., admin areas vs. public corridors)

Restricted keyways prevent unauthorized duplication and allow facility teams to maintain documented issuance and return procedures.

2. Compatibility Assurance

A matching keyway code ensures that cylinders, keys, and interchangeable cores work within the same ecosystem. When ordering replacement keys, additional cylinders, master key expansions, or interchangeable or small format cores, the keyway designation must match. Ignoring it can result in mismatched parts, costly delays, and unusable keys.

The Keyway as the Mechanical Interface

It’s helpful to think of the keyway as the physical handshake between the key and the cylinder. Without a match:

- The key cannot enter

- The pins cannot align

- The lock cannot rotate

- Access cannot be granted

This makes the keyway the first and most fundamental layer of door security.

Even in advanced systems that involve electronics, access control readers, or electrified trim, the mechanical keyway still remains crucial as a fail-safe and override access point.

Maintaining Keyway Integrity

When modifying, expanding, or troubleshooting your door hardware system, always refer back to the original keyway profile. This ensures:

- Scalability of your keying system

- Reduced duplication risk

- Consistency across cores and cylinders

- Long-term security and organizational clarity

The wrong keyway choice can disrupt an entire master key hierarchy or force expensive rework.

Conclusion

Though small and often overlooked, the keyway plays a critical role in how mechanical security systems function. It identifies which key blank can enter a cylinder, helps manufacturers control duplication, and keeps master keying structures organized and secure.

In short, the keyway is not just a slot — it is the customized internal roadmap that allows only the correct key to engage with the lock.

When ordering replacements, scheduling rekeys, or planning system expansions, always verify your keyway code. Doing so ensures that every locking component continues to operate within the parameters of your original security design.