Door hardware plays a vital role in the safety, security, and functionality of any building. Whether it’s a school, office, hospital, or retail space, well-maintained door hardware ensures smooth operation, enhances security, and prolongs the life of your investment. Despite its critical role, door hardware maintenance is often overlooked until something goes wrong. Regular upkeep can prevent costly repairs, mitigate safety risks, and maintain compliance with building codes and standards.

Why Door Hardware Maintenance Matters

- Safety and Security

- Faulty door hardware can compromise a building’s security. A misaligned latch, broken closer, or malfunctioning lock can provide easy access to unauthorized individuals or delay egress during emergencies.

- Regular maintenance ensures panic hardware, exit devices, and locks function correctly, keeping occupants safe.

- Compliance with Codes and Standards

- Building codes require specific types of hardware to be installed and maintained in certain environments. For instance, fire-rated doors must close and latch properly to maintain their fire-resistance integrity.

- ADA compliance also hinges on properly maintained hardware that allows for accessible entry and exit.

- Cost Savings

- Addressing minor issues before they escalate can save money. Preventative maintenance is less expensive than emergency repairs or full hardware replacements.

- Well-maintained hardware reduces wear and tear, extending the life of the components.

- Operational Efficiency

- Doors that don’t operate correctly can slow down traffic flow, causing frustration for employees, customers, or visitors.

- Smooth-functioning hardware minimizes disruptions in daily operations.

Common Door Hardware Maintenance Tasks

- Inspection

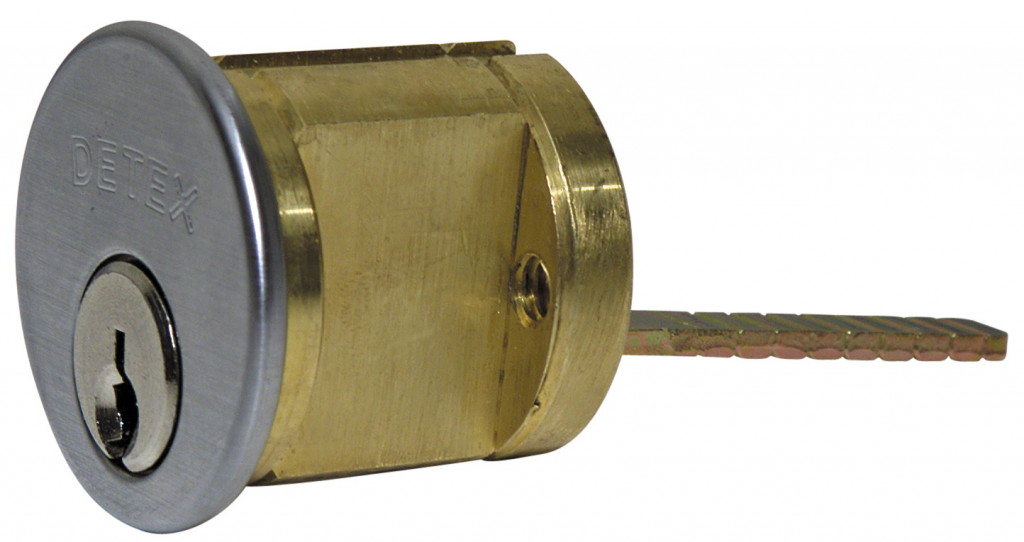

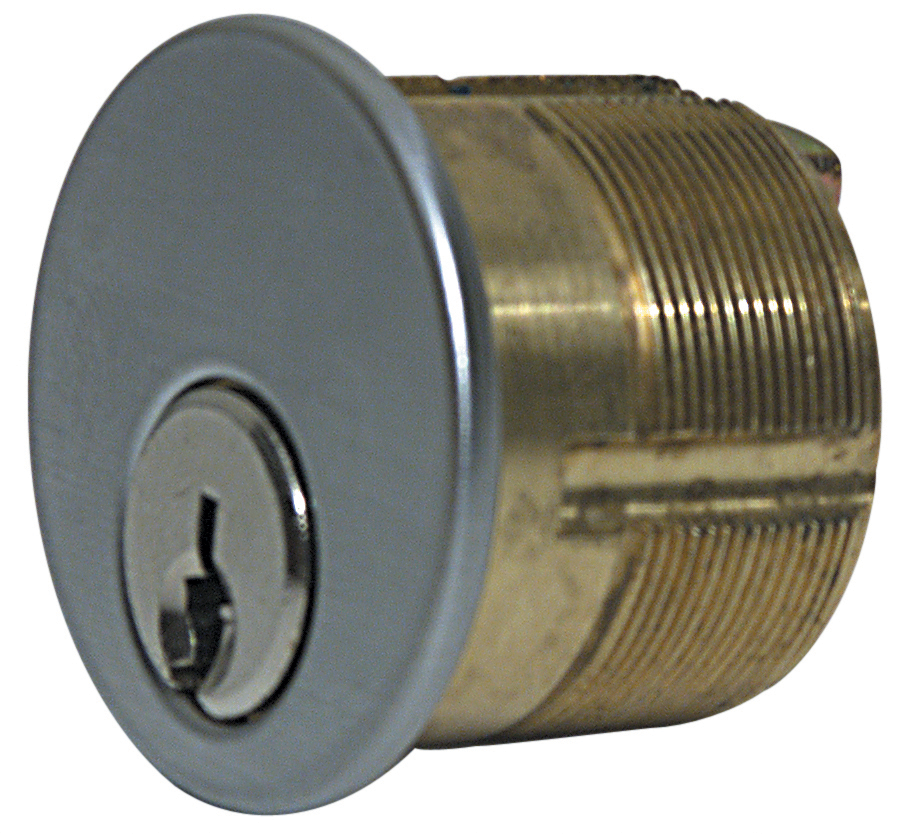

- Regularly check for loose screws, worn hinges, and damaged components. Inspect locks, exit devices, closers, and handles for signs of wear or malfunction.

- Cleaning

- Remove dirt, grease, and grime from hardware to prevent build-up that can impede performance. Use manufacturer-recommended cleaning agents to avoid damaging finishes.

- Lubrication

- Lubricate moving parts such as hinges, locks, and latch mechanisms to ensure smooth operation. Avoid over-lubricating, which can attract dust and debris.

- Alignment

- Ensure doors are properly aligned within their frames. Misalignment can strain hardware components, causing premature failure.

- Testing

- Periodically test panic hardware, door closers, and locks to confirm they’re functioning as intended. Ensure fire doors close and latch automatically.

Tips for Effective Maintenance

- Create a Schedule: Establish a regular maintenance routine tailored to your building’s usage and environment.

- Document Inspections: Keep detailed records of maintenance activities, inspections, and repairs.

- Train Staff: Educate maintenance teams on the correct procedures for maintaining door hardware.

- Partner with Professionals: Work with experienced technicians or hardware manufacturers for comprehensive inspections and repairs.

Conclusion

Investing time and resources into regular door hardware maintenance is essential for ensuring the safety, security, and functionality of your building. By addressing minor issues proactively, you can save money, comply with regulations, and provide a seamless experience for all occupants. Don’t wait for problems to arise—make maintenance a priority and keep your doors operating at their best.